CAS AMT: Applied Manufacturing Technology

ETH Zurich’s CAS programme in Applied Manufacturing Technology (CAS AMT) provides a targeted education in the design and manufacture of engineered products.

The programme is intended for managers and professionals who have no in-depth technical background and would like to broaden their knowledge of new production technologies. The aim of the training is to qualify the participants at the interface to production and development-intensive environments. Participants will learn about the most important processes and technologies driving the transition to Industry 4.0 and their application in practice to develop new and innovative products across various industries.

Download Link to the brochure CAS AMT (PDF, 130 KB)

Download Link to the schedule of CAS AMT FS25 (PDF, 52 KB)

Participants complete the CAS over 14 weeks from January to April. Classes are generally conducted in either a block format or blended learning format to minimize time away from work. Classes are held at ETH Zentrum and ETH Hönggerberg campuses every other week for one full day and one half day (typically Friday all day and Saturday morning). The programme is thus well suited as a part-time study programme.

Total workload is approximately 300 hours (~21 hours/week) and successful graduates earn a total of 12 ECTS credits.

Study language is 100% English.

Prof. Dr. Ralph Spolenak, Dr. Ming Chen

This module discusses the most important manufacturing processes and technologies driving Industry 4.0, including both traditional and advanced manufacturing.

Participants will develop a better understanding of typical manufacturing processes relevant to today’s major industry sectors. The course will cover a wide variety of modern forming, shaping and joining techniques such as casting & injection molding, machining and coating. Further, it will introduce advanced technology such as non-conventional machining, micromanufacturing and additive manufacturing and call attention to current and future trends in manufacturing. Differences in capabilities between processes will be explored to help understand the impact these technologies have in current and future manufacturing processes. The course will further present critical technology related to monitoring and quality assurance, control and automation of manufacturing processes. In general, the module will reveal the fundamental link between materials properties and processing, and will thus provide a basis for the discussion of product design considerations from the viewpoint of manufacturing processes.

Prof. Dr. Stephan Verhasselt

The module deals with the technology and principles that are used to manage systems of production, i.e. combinations of manufacturing processes and support processes such as logistics.

Participants will learn about a variety of typical industry production systems including their applicability in defined business environments and situations. The basics of production management will be reviewed along with factory planning & scheduling and frequently used performance measurements. This will set the stage for discussing performance improving approaches like lean production and production automation. Finally, we will explore how evolving trends and new technology (such as modular layouts, digitalization and computer integrated manufacturing, robotics, etc.) are impacting a number of practical considerations, including quality assurance & productivity, batch sizes and customization, data sharing and external relationships, etc.

Prof. Dr. Mirko Meboldt, Dr. Daniel Omidvarkarjan

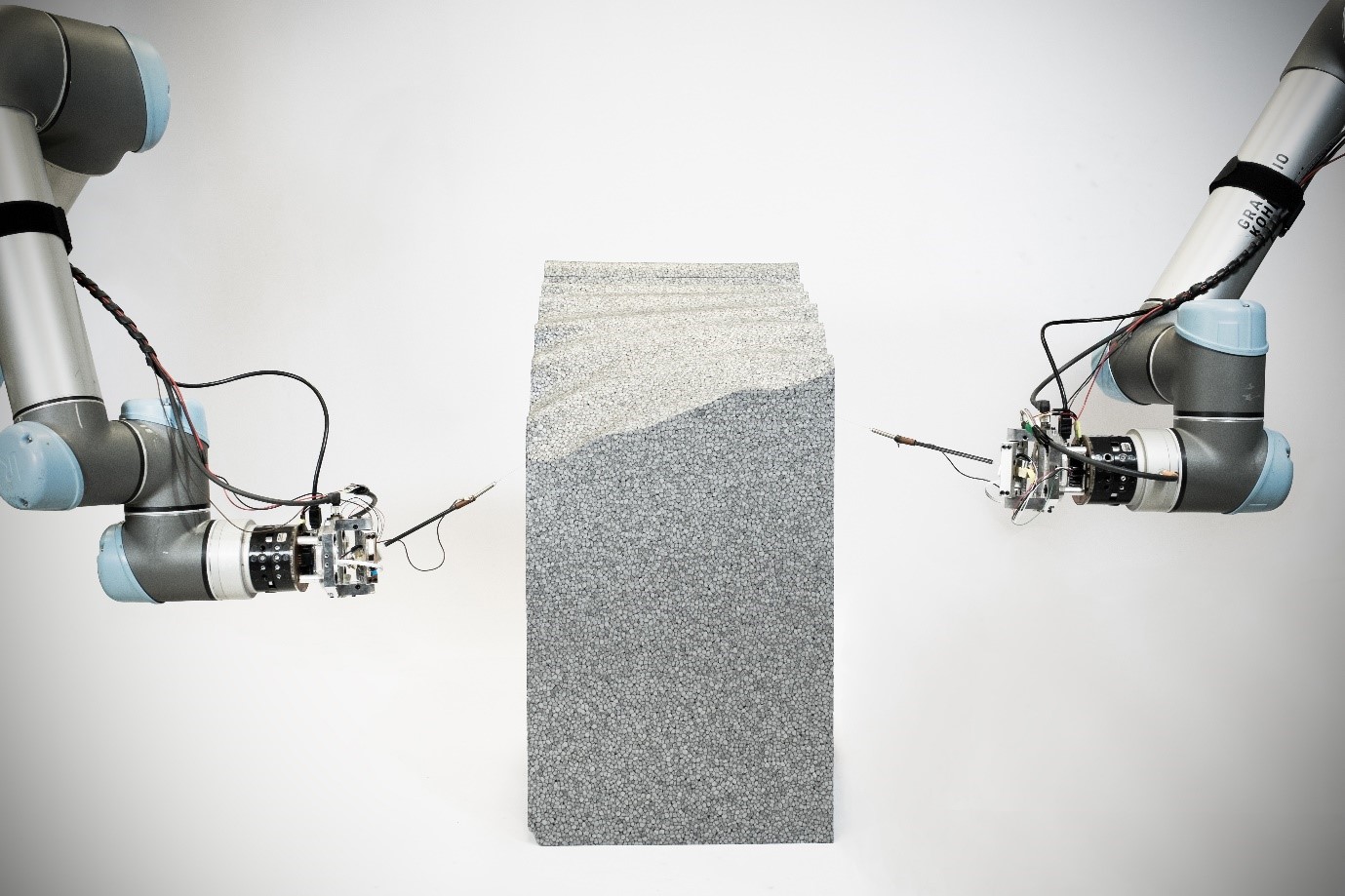

The module focuses on agile product development and the implementation of new technologies using additive manufacturing as an example.

Agile product development is gaining high interest in many industries. Within this module, the participants will be introduced to basic principles, methods and mindset of Agile development by solving a practical development task in teams. Participants will have the opportunity to experience state of the art prototyping tools and methods to realize prototypes.

In the second part of this module the focus is on the implementation of additive manufacturing. New technologies in manufacturing offer great opportunities to improve the overall production process as well as to increase the product’s value for the customer. At the same time they impose a couple of challenges to the established processes. The company needs to understand the new technologies with their advantages and disadvantages in context of their own products and value chains in order to identify the right applications. In general the integration of new technologies into a company requires more agile approaches in order to build up the required knowledge in an effective and efficient way.

Prof. Dr. Ralph Spolenak

This module provides fundamental training in the behavior and manufacturing properties of materials as well as an introduction to materials selection and design considerations.

The structure-property-processing relationship and typical applications of common materials will be reviewed, including metals, polymers (plastics), ceramics and composites. Participants will learn about the mechanical behavior of materials during testing and manufacturing, e.g. strengthening of metals by the appropriate processing. The course will review basic principles and design considerations related to materials selection as practiced in industry, including related concepts such as Design for Manufacturing and “green” design.

CAS AMT applicants* must satisfy the following requirements:

- Demonstrated managerial or equivalent professional experience

- Good knowledge of English

- ETH recognized Master’s degree

CAS AMT applications will be reviewed by the Admission Committee of the Certificate Programme. The final decision is communicated in writing.

* MAS AT applicants do not need to apply to the CAS AMT separately. The background of MAS AT applicants is evaluated during the MAS application review process and there are no further requirements outside of that process.

Please apply online through the School for Continuing Education website.

After submitting the application and uploading supporting documentation, you will be asked to pay the application fee. See the Application section of our website for more information on How To Apply as well as Selection & Admission.

The deadline for applying to the CAS AMT is 30 November.

For MAS in Applied Technology participants, this CAS introduces participants to technologies and concepts that are critical for understanding modern production systems (Industry 4.0) and the opportunities for product innovation.

MAS in Applied Technology Structure